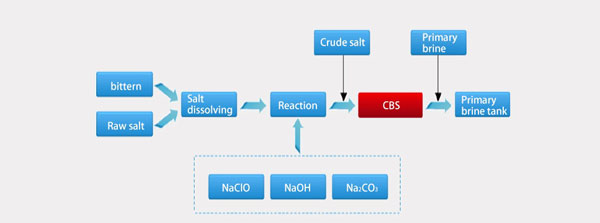

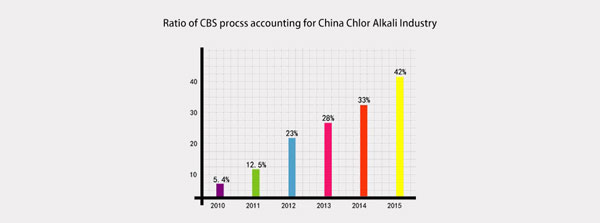

Ceramic Membrane Brine Purification Solution (hereinafter called CBS Process) is a well- proven a well- proven brine purification process for brine water treatment, which can guarantee to offer high quality, stable and reliable primary brine for a long-term and is also an advanced process option for chlor-alkali companies.

CBS combines the characteristics of inorganic materials and the use of efficient "cross-flow" filtration which has greater advantages over other purification technologies.

CBS process can also be used for bittern vacuum salt making and the quality of solid salt produced is higher than that of clarification process which can be used as high-quality edible salt or chloralkali salt. This process involves salt water filters and salt water purifiers for salt water filtration, salt water purification and salt water desalination.

Process characteristics:

Membrane filtration principle

Ceramic membrane filtration technology is based on a selective filtration through a pressure -driven membrane. The membrane has charged groups that selectively reject multivalent anions such as SO42-. The membrane does not separate monovalent ionic species such as Cl- or CLO3- from the feed solution.

To maximize the membrane area within a compact space, the membranes are packaged as cylindrical elements in a spiral wound configuration.

Feed brine floods the entire feed side of the membrane surface within the membrane element by flowing within a mesh spacer. Brine then permeates through the membrane, where the sulfate is rejected, and flows in a spiral pattern through the permeate carrier, towards the perforated permeate tube.

To achieve the required membrane area, several ceramic membrane elements are packed into several high-pressure housing. The high-pressure housings are arranged in series to provide the required number of stages to concentrate the sodium Sulphate solution.

The membrane filtration unit usually treats dechlorinated depleted brine from the chlor-alkali electrolyzer. It is at this location that the Na2SO4 concentration is at its highest and the NaCl concentration is at its lowest. Normally only a portion of the dechlorinated brine flow needs to be passed through the Sulphate removal system, the remainder bypasses the Sulphate remove system and is returned to the saturators.

Features:

1. Reduced purge of depleted brine

we will contact you within 24 hours.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español